Wood Joints in Carpentry

JOINTING BLOCKS

Made from plastic, these are just sophisticated versions of the wooden blocks you can make yourself, and they’re used in similar situations. Their only real advantage is that they tend to give a neater result when you’re working with veneered or melamine covered chipboard, but only because they come in the right colours. There are basically two kinds to choose from.

The simplest is just a hollow triangular ‘block’ that comes with a snap-on cover to hide the screws. More complicated versions come in two parts. You screw one half of the block to each piece of wood, and then screw the two halves together using the machine screw provided. It’s essential here that both halves of the block are positioned accurately, and since the blocks vary from brand to brand in the details of their design, you should follow the manufacturer’s instructions on this point.

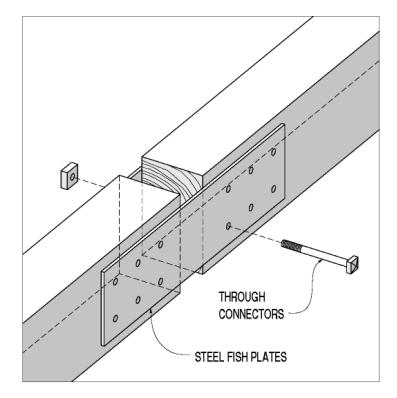

ANGLE IRONS JOINT PLATES

If still greater strength is needed, use either an angle iron or a corner repair bracket to reinforce the joint. These are really just pieces of metal pre-drilled to take screws and shaped to do the same job as a reinforcing block (the angle irons) or to be screwed to the face of the two pieces of timber across the joint (the flat T-shaped and L-shaped corner repair brackets).

In either case, bring together the pieces of wood to be joined, position the bracket, and mark the screw holes. Drill clearance and pilot holes for all the screws, then screw the bracket to one of the pieces before glueing the joint together and screwing the bracket to the second piece. They don’t look very attractive, so use where appearance isn’t important, ie, at the back of a joint, or where the joint is going