CLEARING BLOCKAGES

There are few plumbing emergencies quite as unpleasant as a blocked drain or waste pipe. However, it’s usually possible to cure the problem if you know what to do when you’ve tracked down the blockage and you have the right equipment.

Professional plumbers rarely relish being called out to deal with a blockage. There are specialist drain clearance firms, but they can’t always be contacted quickly in an emergency – and their charges reflect what can sometimes be the unpleasantness of the job. Drain or waste-pipe clearance is usually well within the capacity of the householder, and there are certainly few more cost-effective do-it-yourself jobs about the house.

Coping with blocked sinks

The outlet of the sink, usually the trap immediately beneath the sink itself, is the commonest site of waste-pipe blockage. Usually the obstruction can be cleared quickly and easily by means of a sink-waste plunger or force cup. This is a very simple plumbing tool obtainable from any do-it-yourself shop, ironmongers or household store. It consists of a rubber or plastic hemisphere, usually mounted on a wooden or plastic handle. Every household should have one.

To use it to clear a sink waste blockage, first press a damp cloth firmly into the overflow outlet, holding it securely with one hand. Then pull out the plug and lower the plunger into the flooded sink so that the cup is positioned over the waste outlet. Plunge it up and down sharply half a dozen or more times. Since water cannot be compressed, the water in the waste between the cup and the obstruction is converted into a ram to clear the blockage.

The overflow outlet is sealed to prevent the force being dissipated up the overflow. If your first efforts at plunging are unsuccessful, persevere. Each thrust may be moving the obstruction a little further along the waste pipe until it is discharged into the drain gully or the main soil and waste stack. Should plunging prove unsuccessful you’ll have to gain access to the trap. Brass and lead U-shaped traps have a screwed-in plug at the base. With plastic U-shaped and bottle traps the lower part can be unscrewed and removed – see Ready Reference. Before attempting this, put the plug in the sink and place a bucket under the trap; it will probably be full of water unless the blockage is immediately below the sink outlet, and the chances are that opening the trap will release it. Having done so, probe into the trap, and into the waste pipe itself.

You can buy purpose-made sink waste augers for this purpose, but you’ll find that a piece of expanding curtain wire, with a hook on the end, can be equally effective.

Blocked baths and basins

Basin and bath wastes are less likely to be totally blocked than sink wastes but, when blockages do occur, they can usually be cleared in the same way. They are, however, very subject to partial blockage. The waste water is often found to run from the bath or basin ever more slowly. This may be due to a build-up of scum, scale and hair on the inside of the waste pipe, and the use of a proprietary drain-clearing chemical will usually clear it.

These frequently have a caustic soda base, so they should be kept away from children and handled with care, strictly in accordance with the manufacturer’s instructions. Before spooning them into the bath or basin waste outlet it is wise to smear petroleum jelly over the rim of the outlet to protect the chromium finish, especially with plastic baths or fittings. Partial blockage of a wash basin waste may often be caused by hair suspended from the grid of the outlet. This may be all but invisible from above, but probing with a piece of wire (the old standby of a straightened- out wire cotahanger is useful) can often produce festoons.

If you can’t clear the hair by this means, unscrew the nut that connects the threaded waste outlet to the trap and pull the trap to one side. Now use a pair of pliers to pull the hair away from beneath the grid.

Overflows from gullies

Where waste pipes and downpipes discharge into gullies, the first signs of trouble may be when the gully overflows and the surrounding area is flooded as a result. The gully trap has probably become blocked, either by blown leaves or other debris, or by a build-up of grease and scum on the sides of the trap. Raise the gully grid if one is fitted (and get a new one if it’s broken or missing). Then scoop out any debris with a rubber-gloved hand or an improvised scoop, scrub the gully out with caustic soda and flush it through with plenty of clean water before replacing the grid.

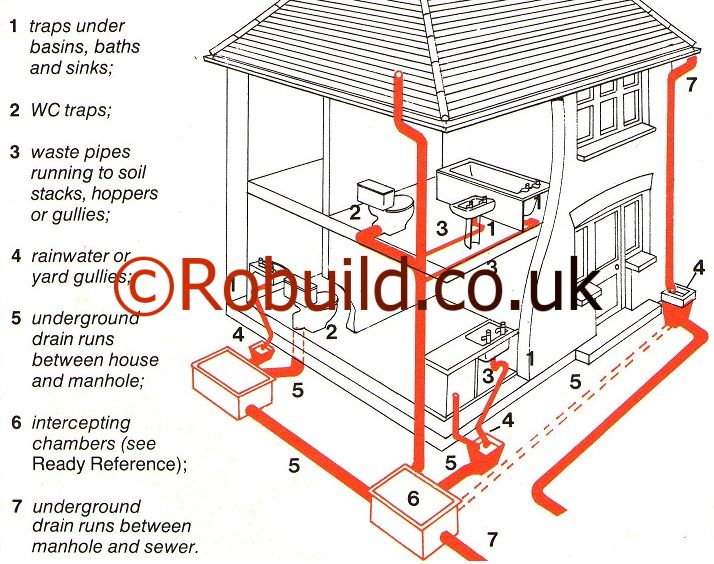

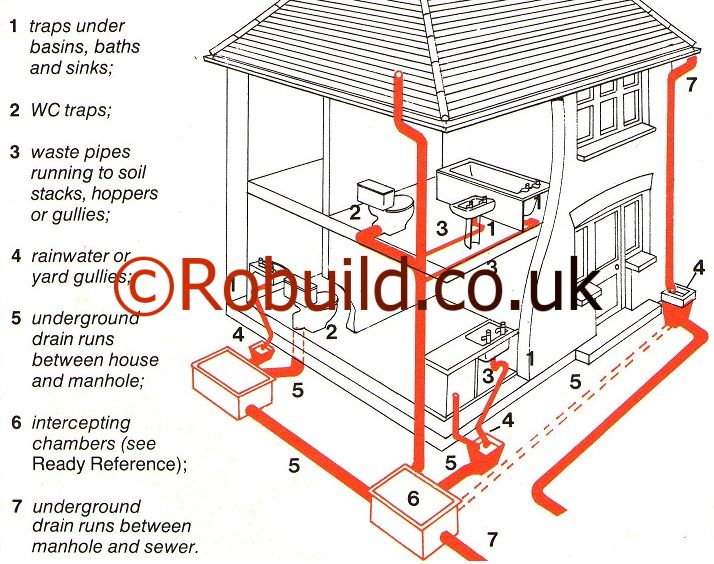

Blockages below ground

A blockage in the underground drains may be shown up by a WC which, when flushed, fills with water almost to the rim and then very slowly subsides, or by dirty water seeping from under a manhole cover. You’ll need a set of drain rods to clear any underground blockage. It is best to hire these from a local tool hire firm if and when the emergency arises.

A drain that blocks sufficiently frequently to justify the purchase of a set of rods undoubtedly has a major defect that needs professional advice and attention. Raising the manhole covers will give you an indication of the position of the blockage. If, for instance, the manhole near your front boundary is empty, but the one beside the house into which the soil pipe and yard gully discharges is flooded, then the blockage must be between these two manholes. Screw two or three lengths of drain-rod together, add the appropriate accessory to one end and then lower it into the flooded manhole. Feel for the drain half-channel at its base and push the rod end along it and into the drain towards the obstruction.

Screw on extra rods as necessary until you reach and clear the blockage. You may find it easier to push the rods into the drain – and to extract them again – if you twist them as you do so. Always twist in a clockwise direction.

If you twist anti-clockwise the rods will unscrew and one or more lengths will be left irretrievably in the drain. Many older houses have intercepting traps. These traps, which were intended to keep sewer gases out of the house drains, are the commonest site of drain blockage. You can see if your drains have an intercepting trap by raising the cover of the manhole nearest to your property boundary before trouble occurs and looking inside. If there is an intercepting trap the half-channel of the gully will fall into what appears to be a hole at the end of the manhole; actually it is the inlet to the trap. Immediately above this hole will be a stoneware stopper. This closes the rodding arm giving access to the length of drain between the intercepting trap and the sewer.

A blockage in the intercepting trap is indicated when all the drain inspection chambers are flooded. It can usually be cleared quite easily by plunging. To do this, screw a drain plunger (a 4in or 100mm diameter rubber disc) onto the end of a drain rod. Screw on one or two other rods as necessary and lower the plunger into the flooded manhole. Feel for the half-channel at its base and move the plunger along until you reach the inlet of the intercepting trap. Plunge down sharply three or four times and, unless you are very unlucky, there will be a gurgle and the water level in the manhole will quickly fall.

Very occasionally, there may be a blockage between the intercepting trap and the sewer, and the point must be made that this length of drain is the householder’s responsibility, even though much of it may lie under the public highway. To clear such a blockage the stoneware cap must be knocked out of the inlet to the rodding arm (this can be done with the drain rods but it isn’t the easiest of jobs) and the rods passed down the rodding arm towards the sewer. Intercepting traps are also subject to a kind of partial blockage that may go unnoticed for weeks or even months. An increase in pressure on the sewer side of the trap – due to a surge of storm water, for instance – may push the stopper out of the rodding arm.

It will fall into the trap below and cause an almost immediate stoppage. However this will not be noticed because sewage will now be able to escape down the open rodding arm to the sewer. The householder usually becomes aware of a partial blockage of this kind as a result of an unpleasant smell, caused by the decomposition of the sewage in the base of the manhole. The remedy is, of course, to remove the stopper and to replace it. Where the trouble recurs it is best to discard the stopper and to lightly cement a glass or slate disc in its place. In the very unusual event of a stoppage between the intercepting trap and the sewer, this disc can be broken with a crowbar and replaced after the drain has been cleared. After any drain clearance the manhole walls should be washed down with a hot soda solution and a garden hose should be used to flush the drain through thoroughly.